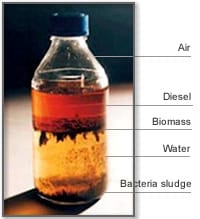

Unfortunately, fuel is not delivered from the refinery to the consumer in an air-tight drum. It typically travels by pipeline, ship, and truck, coming into contact with several common contaminants — including other distillate fuels — on its way down the supply chain. Water, the most common and most harmful contaminant to distillate fuel, can enter the fuel during refining, storage, transportation and/or delivery, and is virtually impossible to eliminate completely. Common scenarios include rainwater seeping in through the roof or vent of a tank, or humid air carrying moisture in during a fuel withdrawal. Once in the tank, water promotes the proliferation of microbial life — bacterial cells or fungal spores known in the industry as “bugs” — which will live in the water at the bottom of the tank and feed off the hydrocarbons at the fuel/water interface. Bugs will also consume rubber gaskets, O-rings, hoses, tank linings and coatings in an effort to obtain their mineral content. The waste from this process produces more water, sludge, acids and other harmful byproducts. If not addressed, the proliferation of bugs will clog fuel filters, fuel lines and gauges; corrode pumps, injectors and tank bottoms; cause washers, hoses and connectors to swell and blister; degrade fuel, and cause poor fuel economy. To prevent this, fuel storage facilities should be sampling and analyzing their fuel three to four times a year—especially during seasonal changes, when there are frequent swings in temperatures. As frigid winter air gives way to cool spring nights and warmer days, for instance, the alternating temps will conspire to create condensation within the tank, a leading cause of water contamination. AFS will sample your fuel in storage and give a detailed report of any found contaminants, offer to eliminate them, and empower you to prevent them from occurring again.

Unfortunately, fuel is not delivered from the refinery to the consumer in an air-tight drum. It typically travels by pipeline, ship, and truck, coming into contact with several common contaminants — including other distillate fuels — on its way down the supply chain. Water, the most common and most harmful contaminant to distillate fuel, can enter the fuel during refining, storage, transportation and/or delivery, and is virtually impossible to eliminate completely. Common scenarios include rainwater seeping in through the roof or vent of a tank, or humid air carrying moisture in during a fuel withdrawal. Once in the tank, water promotes the proliferation of microbial life — bacterial cells or fungal spores known in the industry as “bugs” — which will live in the water at the bottom of the tank and feed off the hydrocarbons at the fuel/water interface. Bugs will also consume rubber gaskets, O-rings, hoses, tank linings and coatings in an effort to obtain their mineral content. The waste from this process produces more water, sludge, acids and other harmful byproducts. If not addressed, the proliferation of bugs will clog fuel filters, fuel lines and gauges; corrode pumps, injectors and tank bottoms; cause washers, hoses and connectors to swell and blister; degrade fuel, and cause poor fuel economy. To prevent this, fuel storage facilities should be sampling and analyzing their fuel three to four times a year—especially during seasonal changes, when there are frequent swings in temperatures. As frigid winter air gives way to cool spring nights and warmer days, for instance, the alternating temps will conspire to create condensation within the tank, a leading cause of water contamination. AFS will sample your fuel in storage and give a detailed report of any found contaminants, offer to eliminate them, and empower you to prevent them from occurring again.