Oil storage facilities should be as diligent in keeping water out of petroleum as they are in keeping petroleum out of water.

When oil and water mix, oil is always portrayed as the contaminant. While certainly true that large volumes of oil can be catastrophic to aquatic environments—that’s why the EPA requires every major oil storage facility to have an up-to-date Spill Prevention Countermeasures and Containment (SPCC) plan—what about when water is the contaminant?

The situation may be less concerning to the EPA, but when water enters an oil tank, it can be every bit as damaging to the fuel as oil contamination is to a body of water. In the event of the former, it is important that oil storage facilities have a plan in place—an SPCC equivalent—to combat water contamination, and to minimize damage when it occurs. Failing to do so can result in fuel degradation, equipment breakdowns, significant labor and repair costs, and lost business.

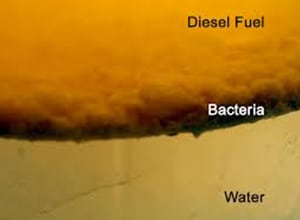

Water is both the most common and most harmful contaminant to distillate fuel. It can get into the fuel during refining, storage, transportation and delivery, and is virtually impossible to eliminate completely. Common scenarios include rainwater seeping in through the roof or vent of a tank, or humid air carrying moisture in during a fuel withdrawal. Once in the tank, water is harmful in the exact opposite way that oil is harmful to water: while oil threatens life in water, water promotes life in petroleum.

This air and waterborne microbial life—bacterial cells or fungal spores known in the industry as “bugs”—will live in the water at the bottom of the tank and feed off the hydrocarbons in the fuel at the fuel/water interface. They’ll also consume rubber gaskets, O-rings, hoses, tank linings and coatings in an effort to obtain their mineral content. The waste from this process produces water, sludge, acids and other harmful byproducts. Under the ideal conditions of a warm spring or summer day (68-86 degrees Fahrenheit), bacteria can double in population every 20 minutes, forming destructive, gel-like colonies known as biofilms. If not addressed, the proliferation of bugs will clog fuel filters, fuel lines and gauges; corrode pumps, injectors and tank bottoms; cause washers, hoses and connectors to swell and blister; degrade fuel, and cause poor fuel economy.

If microbial contamination is detected—either by visual observation of a fuel filter or bottom sample, or by analytical laboratory testing—cleanup can be both difficult and expensive. In all cases, water bottoms should be drained and a biocide should be added to treat the remaining fuel. While in some instances it may only be necessary to filter the treated fuel, more severe cases will require physical removal of floating biofilm or bottom sludge. Depending on the severity of the problem, manual cleaning of the tank may be required before refueling to remove any remaining debris or corrosive byproduct from the interior surface.

Good housekeeping is the best and most cost-effective preventative measure against microbial contamination. Water should be drained from storage tanks at least every six months, and especially before the start of winter. If all water can’t be removed, the remaining in-tank water should be treated with a water-soluble biocide—also every six months—or the pH level of the water should be raised to a level that is less conducive to microbial growth (pH 9.0 or higher). Fuel tanks should be kept at or near capacity to minimize contamination due to the condensation of moist air in the tank. Lastly, tank bottoms should be sampled and analyzed every three to four months. Periodic sampling is an essential part of any preventative program. While water will undoubtedly be detected, with a sound maintenance program in place, microbial growth will not.

For general housekeeping tips and services, or for specific consultation regarding the detection, removal, or prevention of water and microbial contamination (or any other fuel quality issue), contact Advanced Fuel Solutions (www.yourfuelsolution.com) at 978-258-8360 or lou@yourfuelsolution.com.